Introduction

In the world of building services and industrial processes, maintaining water quality is crucial for efficiency, reliability, and long-term performance. Closed water systems, such as those used in heating and chilled water applications, are particularly vulnerable to corrosion, scale, and microbiological growth if left untreated. One of the most effective tools for introducing and maintaining chemical treatment in these systems is the dosing pot.

Although compact and relatively simple in design, dosing pots play an indispensable role in ensuring the smooth operation of heating and cooling systems. This article explores what they are, how they work, and why they are a key component in any water treatment strategy.

What Is a Dosing Pot?

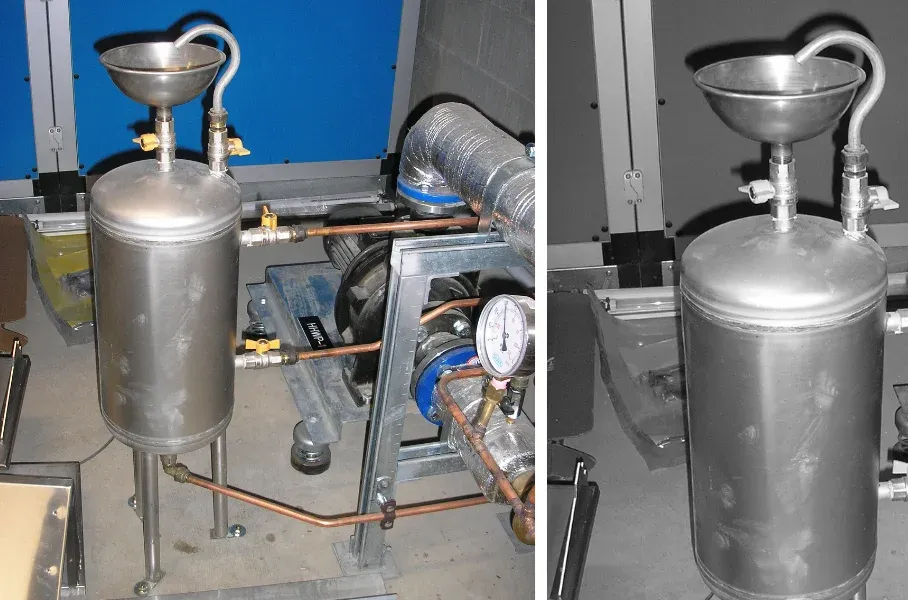

A dosing pot is a device installed on closed water systems to enable the safe and controlled introduction of chemical solutions, such as inhibitors, biocides, or cleaning agents. It is typically a cylindrical vessel, usually made from mild steel or stainless steel, and fitted with inlet and outlet valves, a drain, and a vent.

The design allows operators to add treatment chemicals without interrupting the flow of the main system. This is especially important in critical environments such as hospitals, manufacturing plants, and office buildings, where shutting down heating or cooling systems is not practical.

Why Dosing Pots Are Important

1. Protecting Against Corrosion

Corrosion is one of the greatest risks in closed water systems. Without proper treatment, oxygen and contaminants can cause pipes, heat exchangers, and equipment to degrade over time. A dosing pot ensures corrosion inhibitors are introduced effectively, extending the life of the system.

2. Preventing Scale Formation

Minerals such as calcium and magnesium can lead to scale deposits, which reduce system efficiency and increase energy costs. By dosing descalants or inhibitors, dosing pots help maintain smooth surfaces within pipework and heat exchangers.

3. Controlling Bacterial Growth

In chilled water systems, bacteria such as pseudomonas can flourish if untreated. Biocides can be safely added via dosing pots, reducing the risk of biofilm formation and associated health hazards.

4. Maintaining System Balance

Dosing pots make it easy to adjust chemical levels when system water is tested. This ensures consistent water quality and avoids the costly consequences of chemical imbalance.

How Dosing Pots Work

The principle of operation is straightforward:

- Isolation: The pot is isolated from the main system using inlet and outlet valves.

- Filling: The vent is opened, and the pot is filled with the required chemical solution.

- Sealing: The vent is closed, and the pot is reconnected to the system by opening the valves.

- Mixing: As water flows through, the chemicals are drawn into the main circuit, evenly distributing treatment throughout the system.

This simple but effective method ensures precise control and safe handling of treatment chemicals.

Types of Dosing Pots

While the basic principle remains the same, dosing pots are available in different designs to meet specific system needs.

Standard Mild Steel Dosing Pots

- Cost-effective and durable.

- Commonly used in heating and chilled water systems.

- Suitable for general-purpose water treatment chemicals.

Stainless Steel Dosing Pots

- Resistant to corrosion.

- Ideal for aggressive or specialised chemical applications.

- Preferred in high-spec environments such as food production or pharmaceuticals.

Bespoke or Large-Capacity Dosing Pots

- Designed for systems requiring higher chemical volumes.

- Can be tailored with additional features, such as gauges or quick-release fittings.

Applications Across Sectors

Commercial Buildings

In office blocks, schools, hospitals, and shopping centres, HVAC systems rely on effective water treatment. Dosing pots allow facilities teams to maintain water quality without disrupting operations.

Industrial and Manufacturing Facilities

Processes that depend on precise temperature control, such as chemical production or data centres, cannot risk inefficiency due to fouling or corrosion. Dosing pots ensure reliability and protect critical equipment.

Energy and Utilities

District heating systems, power plants, and renewable energy facilities often involve large, complex closed loops. Dosing pots are essential for keeping these systems operating at peak efficiency.

Specialist Environments

In laboratories, pharmaceutical plants, and food processing industries, strict water quality standards are non-negotiable. Stainless steel dosing pots provide a safe and compliant solution.

Benefits of Using Dosing Pots

- Improved System Longevity

By preventing corrosion, scaling, and bacterial growth, dosing pots protect equipment, saving money on replacements and repairs. - Energy Efficiency

Scale and fouling increase resistance in heat exchangers, forcing systems to use more energy. Regular dosing ensures peak efficiency and lower energy bills. - Reduced Downtime

Maintenance teams can add chemicals without interrupting system operation, avoiding costly downtime. - Safe Chemical Handling

The controlled design of dosing pots reduces the risk of operator exposure to potentially hazardous chemicals. - Compliance with Standards

Many industries require documented water treatment regimes. Dosing pots help ensure systems meet compliance requirements such as BSRIA and CIBSE guidelines.

Key Considerations When Selecting a Dosing Pot

When choosing the right dosing pot for a project, engineers and facilities managers should consider the following:

- Capacity: Ensure the vessel can hold the necessary chemical volume for your system.

- Material: Choose mild steel for general use or stainless steel for more aggressive environments.

- Installation: Placement should allow easy access for operators.

- Safety Features: Look for features such as lockable valves, pressure relief devices, or quick-release connections if needed.

- Supplier Support: Working with an experienced supplier ensures correct specification, installation guidance, and ongoing support.

Best Practices for Using Dosing Pots

- Regular Testing: Always test system water before dosing to avoid over- or under-treatment.

- Accurate Records: Keep records of dosing activity to track chemical usage and maintain compliance.

- Scheduled Maintenance: Inspect valves, seals, and connections regularly to ensure safe operation.

- Training: Ensure that staff handling chemicals are trained in safe use and emergency procedures.

The Future of Dosing Technology

While traditional dosing pots remain a proven and reliable solution, advances in automation and smart monitoring are influencing the way water treatment is managed. Digital dosing pumps and real-time monitoring sensors are becoming more common, providing more accurate dosing and automated chemical balance adjustments.

However, dosing pots remain an essential backup, offering simplicity, reliability, and independence from complex control systems. Their continued use alongside modern technologies demonstrates their enduring value.

Conclusion

The dosing pot is a fundamental part of water treatment in closed heating and chilled water systems. By providing a safe, effective, and reliable way to introduce chemicals, they protect infrastructure, reduce costs, and improve efficiency across a wide range of industries.

From commercial buildings to power stations, these small but vital devices ensure water systems operate smoothly and safely. Investing in a well-specified dosing pot is not just good practice—it is an essential step in maintaining system integrity.